ENGINEERING COOKBOOK LOREN COOK COMPANY. Design Criteria for Room Loudness. Centrifugal fans are the ‘workhorse’ of the fan industry.

Applied Calculus 9th Edition Tan Pdf there. Centrifugal fans employ the use of a rotating impeller or wheel to increase the speed of an air stream. Air is discharged at 90 degrees to the inlet airstream. The centrifugal speed increases as the air stream reaches the ends of the fan blades and is then converted to pressure. Centrifugal fans are widely used for industrial processes because of their ability to achieve high system pressures. Optional wheel designs produce differing pressure ranges and CFM possibilities, efficiencies vary and generated noise levels fluctuate.

Some degree of noise attenuation is typically required for an industrial centrifugal fan.

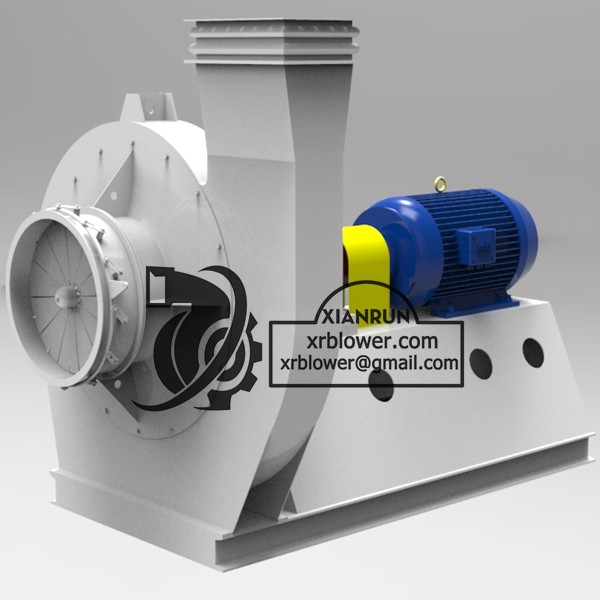

A typical backward-curved centrifugal fan, where the blades curve away from the direction they rotate. A centrifugal fan is a mechanical device for moving or other. The terms 'blower' and 'squirrel cage fan', (because it looks like a ), are frequently used as synonyms.

These fans increase the speed and volume of an air stream with the rotating. Centrifugal fans use the kinetic energy of the to increase the volume of the air stream, which in turn moves them against the resistance caused by ducts, dampers and other components. Centrifugal fans displace air radially, changing the direction (typically by 90°) of the airflow. They are sturdy, quiet, reliable, and capable of operating over a wide range of conditions.

Centrifugal fans are constant displacement devices or constant volume devices, meaning that, at a constant fan speed, a centrifugal fan moves a relatively constant volume of air rather than a constant mass. This means that the air velocity in a system is fixed even though the mass flow rate through the fan is not.

[ ] Centrifugal fans are not positive displacement devices. Centrifugal fans have certain advantages and disadvantages when contrasted with positive-displacement blowers.

The centrifugal fan is one of the most widely used fans. Centrifugal fans are by far the most prevalent type of fan used in the industry today. They are often cheaper than axial fans and simpler in construction. They are used in transporting gas or materials and in ventilation systems for buildings and vehicles. They are also well-suited for processes and control systems.

The centrifugal fan is a drum shape composed of a number of fan blades mounted around a hub. Girl Tech Vj 621 Driver. As shown in the animated figure, the hub turns on a mounted in bearings in the fan housing.